Professional Hydroflex system for sealing deformation and cold seams

The Hydroflex joint sealing system is a professional solution for waterproofing expansion joints, cold joints and cracks in concrete and reinforced concrete structures. It is widely used in civil, industrial and hydraulic engineering, where long-lasting sealing under dynamic loads and water pressure is critical.

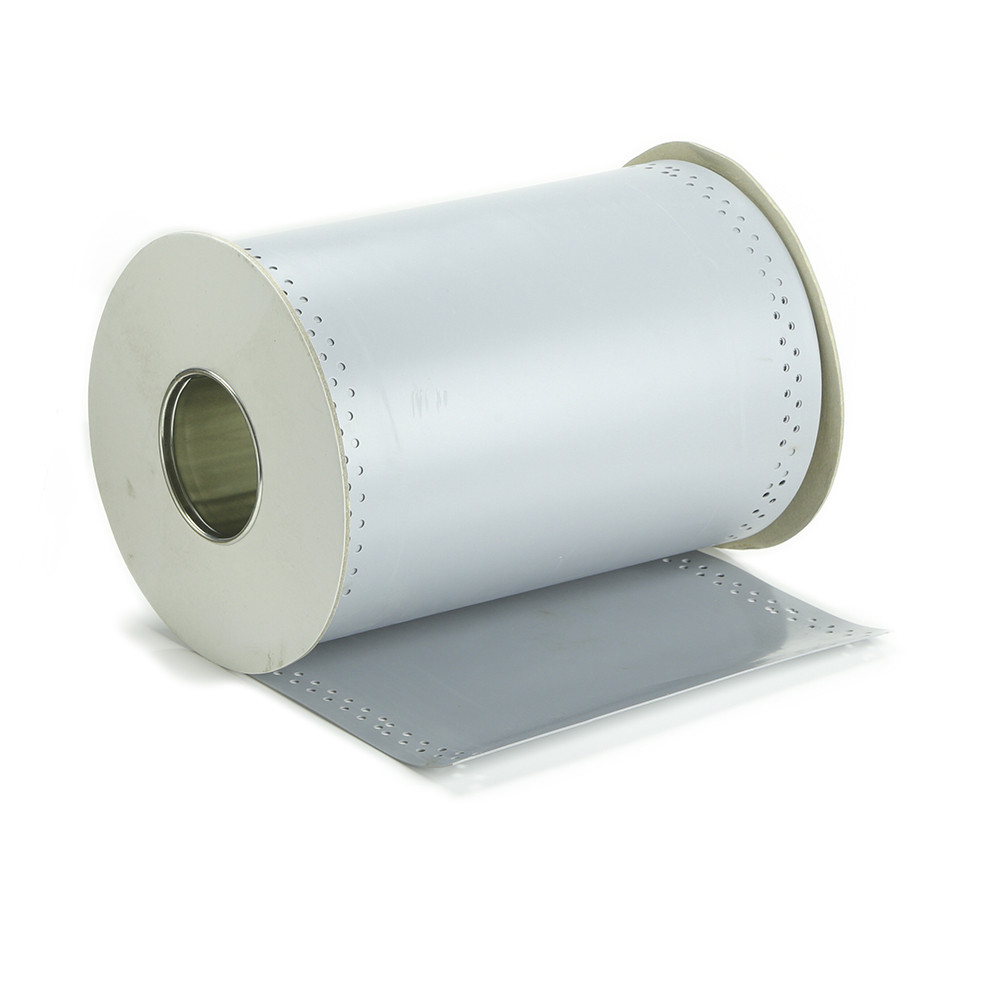

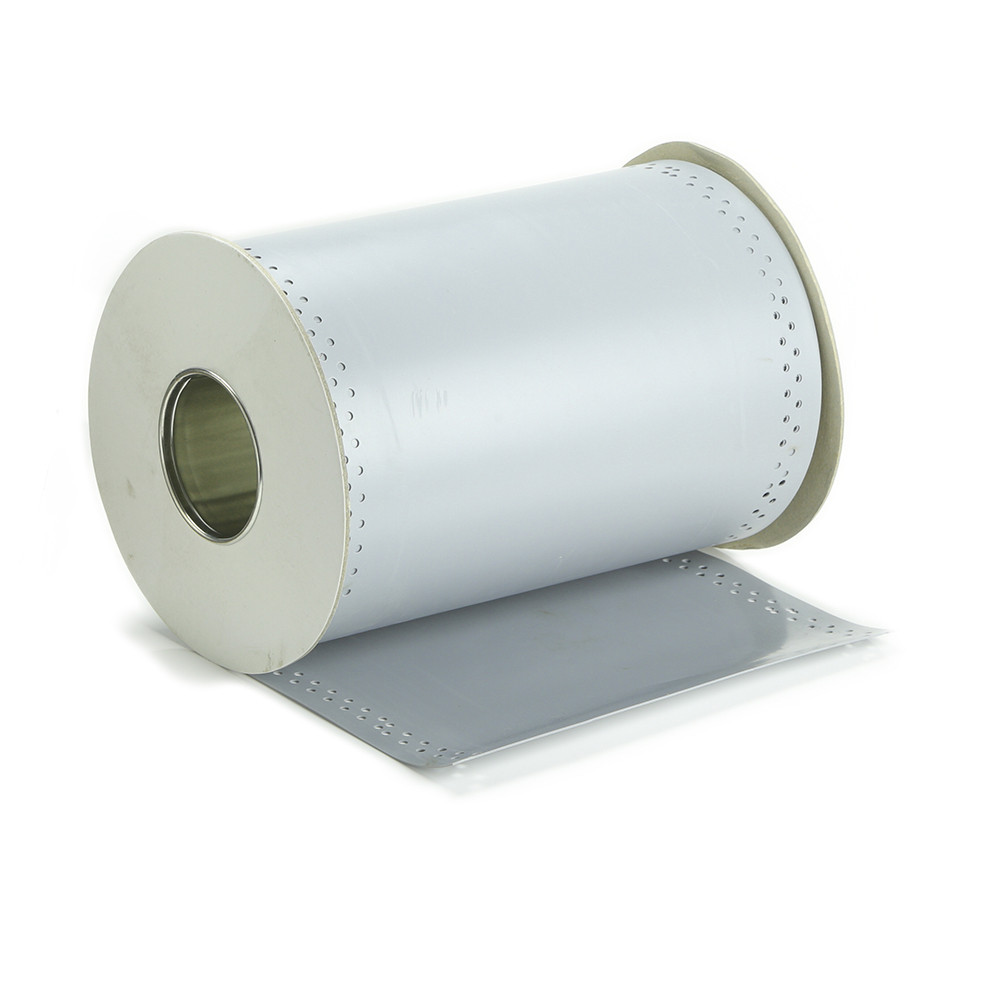

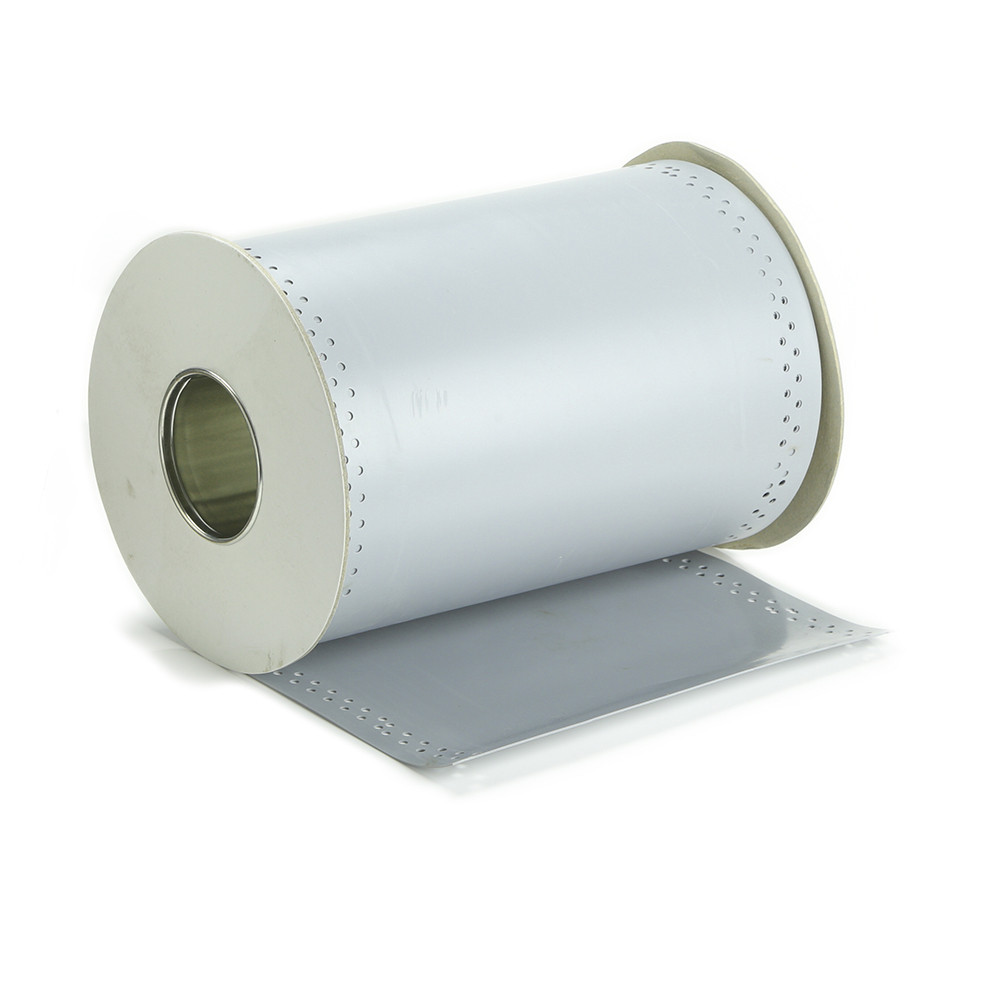

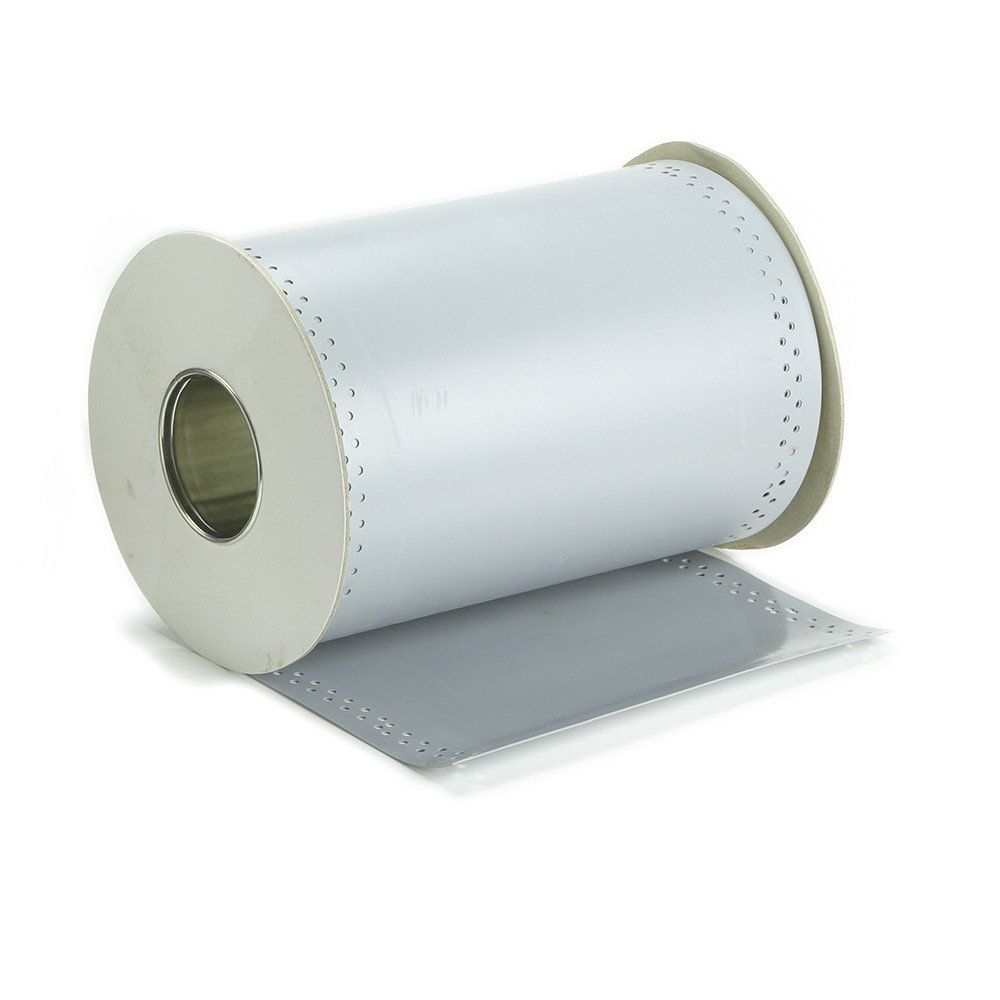

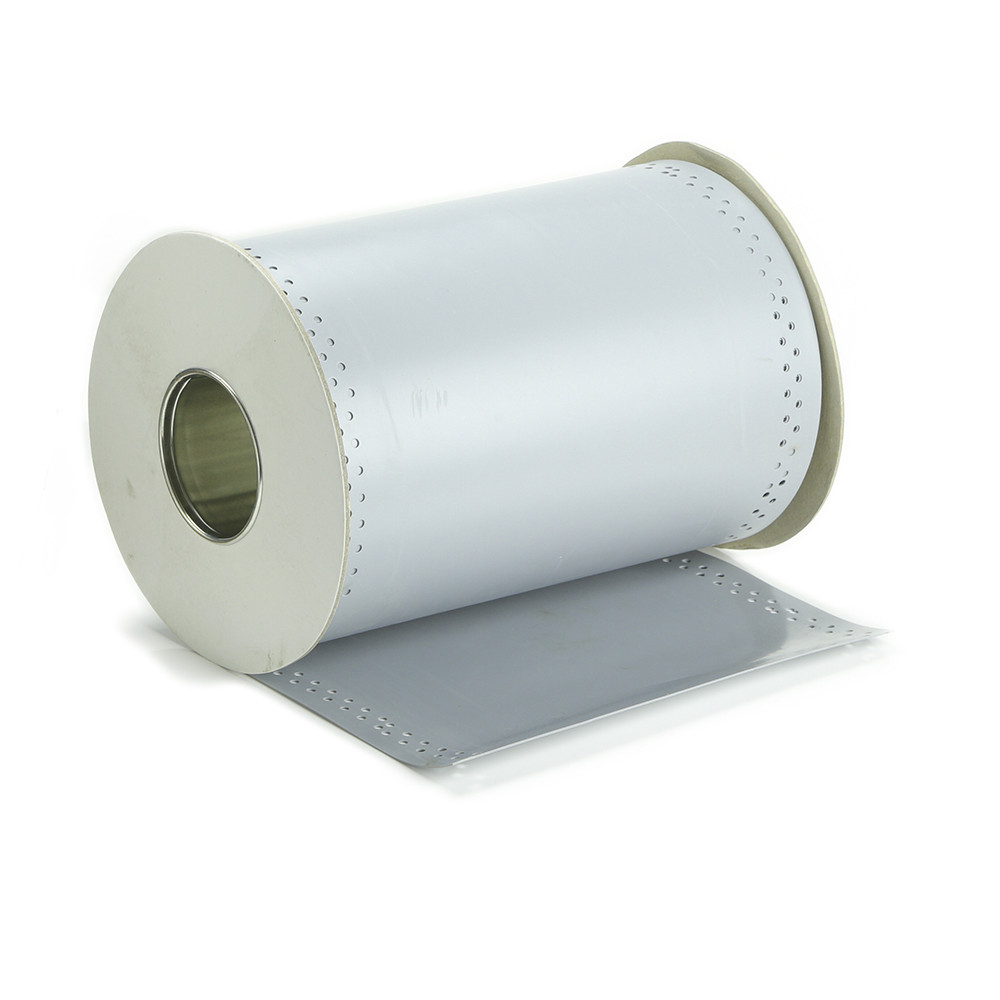

Highly elastic waterproofing tape Hydroflex

Hydroflex waterproofing tape is made of thermoplastic elastomer (TEP) and has unique elasticity indicators - elongation at break up to 600% . This allows you to compensate for deformations of structures in three planes without loss of tightness.

The tape is available in widths of 150, 200, 250, 300 and 400 mm and thicknesses of 1 or 1.5 mm , which allows you to choose the optimal solution for a specific type of seam and load level.

Scope of application of Hydroflex

The Hydroflex system is used for:

-

sealing of expansion joints of buildings and structures (horizontal and vertical);

-

waterproofing of basements, foundations, underground parking lots ;

-

protection of hydraulic structures (pools, tanks, collectors, wells);

-

sealing of tunnels, communication inlets, ventilation holes ;

-

waterproofing of flat roofs ;

-

repair and restoration of existing concrete structures.

The material is approved for use in direct contact with drinking water , which makes it suitable for facilities with increased sanitary requirements.

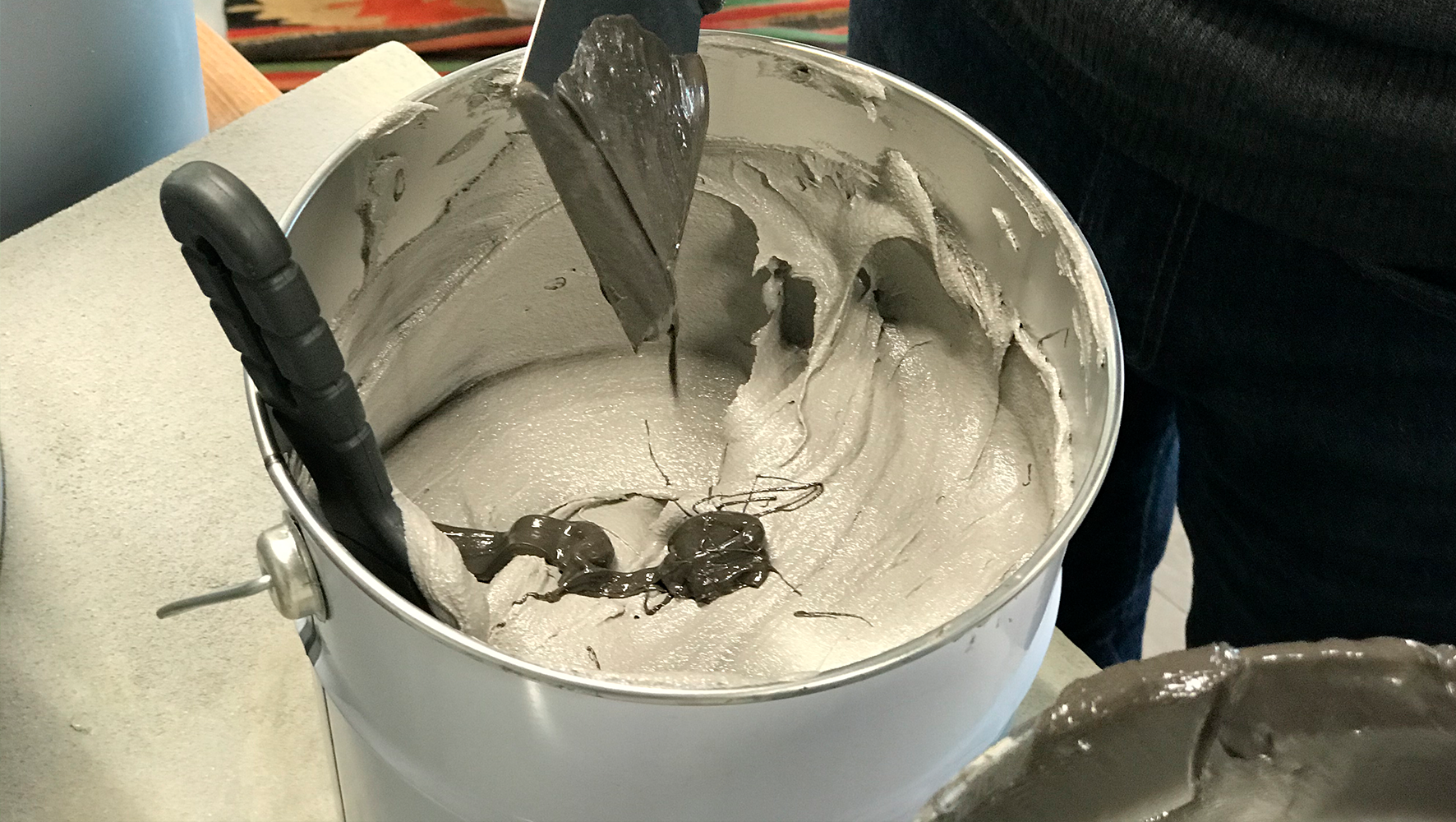

Adhesive and repair mixture Hydroflex 21

The key element of the system is the epoxy adhesive and repair mixture Hydroflex 21 - a two-component polymer composition without solvents. It provides high adhesion of the tape to concrete even on wet surfaces , without the need for priming.

Hydroflex 21 is used for:

-

sealing of loaded and temperature joints;

-

sealing large cracks in concrete;

-

waterproofing of walls and floors;

-

gluing waterproofing membranes, tiles, mosaics.

The composition is characterized by high chemical resistance , wear resistance and water resistance. Mechanical loads are allowed after 5 days , full chemical resistance - after 7 days .

Installation technology

Hydroflex tape is installed by gluing it onto a two-component epoxy adhesive followed by sealing the edges. The tapes are joined together using hot air welding (270 °C) with an overlap of 5–10 cm, which ensures the monolithic nature of the system.

The Hydroflex system is a technically sound solution for sealing expansion joints under conditions of high loads, positive and negative hydrostatic pressure, aggressive environments and significant temperature fluctuations. It meets the requirements of modern construction and provides long-term protection of structures.